| Quantity: 3 Tons |

| Diameter: 1.2mm |

| Length: 1000mm |

| Material: Aluminum Alloy |

Shipbuilding Aluminum Alloy Welding Wire

Shipbuilding often requires the use of specialized welding techniques and materials, including aluminum alloy welding wire. Aluminum alloys are commonly used in shipbuilding due to their lightweight properties and corrosion resistance. Welding aluminum alloys, however, can be more challenging compared to other materials due to their low melting point, high thermal conductivity, and susceptibility to distortion during welding.

When it comes to aluminum alloy welding wire for shipbuilding, there are a few key considerations:

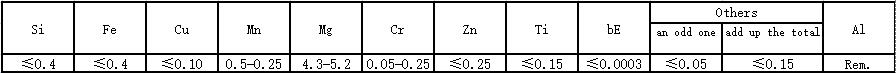

Aluminum Alloy Selection: Choose the appropriate aluminum alloy for the specific application. Common aluminum alloys used in shipbuilding include 5083, 5086, and 6061, among others. Each alloy has its own mechanical properties, corrosion resistance, and welding characteristics, so it's important to select the right one for the ship's intended use.

Welding Process: The choice of welding process depends on the shipbuilding requirements and the specific aluminum alloy being used. Some commonly used welding processes for aluminum include TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), and even laser welding. TIG welding is often preferred for shipbuilding due to its precise control and ability to produce high-quality welds.

Welding Wire: When selecting welding wire for aluminum shipbuilding, it's crucial to choose a wire that matches the alloy being welded. The wire should have a chemical composition and mechanical properties similar to the base metal to ensure proper fusion and joint integrity. Additionally, the wire should be clean and free of contaminants that could lead to weld defects.

Wire Diameter: The wire diameter used for welding aluminum should be chosen based on the thickness of the material being welded. Thicker materials generally require larger diameter wires to ensure adequate weld penetration and strength.

Pre-Weld Preparation: Proper cleaning and preparation of the base metal are essential for successful aluminum welding. Oxide layers on aluminum surfaces can negatively impact weld quality, so thorough cleaning methods such as wire brushing or chemical cleaning may be necessary.

Chemical Composition (weight percent, %)

BACK TO TOP