| Quantity: 1 Tons |

| Diameter: 1.2~3mm |

| Length: 1000mm |

| Material: Aluminum Alloy |

Marine Aluminum Alloy Welding Wire

Marine aluminum alloy welding wire is a specialized type of welding consumable used for joining aluminum alloys in marine applications. Aluminum is commonly used in the marine industry due to its lightweight, corrosion-resistant properties, making it suitable for various components like boat hulls, decks, masts, and other structures. Welding aluminum alloys requires specific techniques and materials due to their unique characteristics, such as high thermal conductivity and susceptibility to porosity.

Welding aluminum alloys in marine environments involves using aluminum alloy welding wires that are designed to match the composition and properties of the base materials. These wires typically have alloy compositions that closely match the composition of the aluminum being welded. They come in various grades and types, each suited for specific applications and welding methods.

Some key considerations when using marine aluminum alloy welding wire include:

Alloy Compatibility: Using welding wire with an alloy composition similar to the base material ensures proper metallurgical bonding and minimizes the risk of galvanic corrosion.

Welding Method: Common welding methods for aluminum alloys include gas tungsten arc welding (GTAW/TIG), gas metal arc welding (GMAW/MIG), and pulse welding. The choice of method depends on factors such as the type of joint, thickness of the material, and available equipment.

Welding Parameters: The choice of welding parameters, such as current, voltage, travel speed, and wire feed speed, should be optimized for the specific alloy being welded.

Quality Control: Regular inspection and quality control procedures should be in place to detect defects like porosity, incomplete fusion, or cracks. Non-destructive testing methods like ultrasonic testing or X-ray inspection might be used.

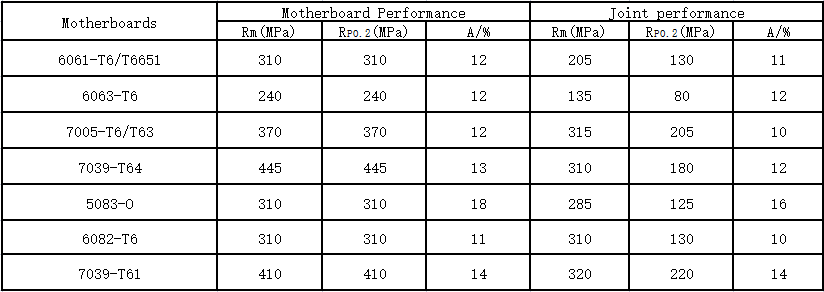

Mechanical Properties of Typical Welding joints (For reference)

BACK TO TOP