| Quantity: 3 Tons |

| Diameter: 1.2mm |

| Length: 1000mm |

| Material: Aluminum Alloy |

Ship Aluminum Alloy Welding Wire

Ship aluminum alloy welding wire is a specialized type of welding consumable used in the maritime industry for joining and repairing aluminum alloy components in ships and boats. Aluminum alloys are commonly used in shipbuilding due to their lightweight, corrosion-resistant, and high-strength properties. Welding aluminum alloys presents unique challenges due to their low melting point, high thermal conductivity, and susceptibility to distortion and cracking.

Key features and considerations for ship aluminum alloy welding wire include:

Aluminum Alloy Compatibility: Ship aluminum alloy welding wires are formulated to match the specific grade of aluminum alloy being welded. Common aluminum alloys used in shipbuilding include 5XXX and 6XXX series alloys, such as 5083, 5086, and 6061, which offer a balance between strength, corrosion resistance, and weldability.

Wire Composition: Ship aluminum alloy welding wires are composed of a core aluminum wire that is coated with a flux or a combination of alloying elements. These coatings help improve arc stability, reduce weld defects, and provide additional alloying elements to enhance the mechanical properties of the weld joint.

Alloying Elements: The coating on ship aluminum alloy welding wire often contains alloying elements like silicon, magnesium, and manganese. These elements aid in controlling the weld's mechanical properties, fluidity, and strength. Additionally, the right alloying elements can help reduce the formation of brittle intermetallic phases that can affect weld integrity.

Flux Core: Some ship aluminum alloy welding wires have a flux core that releases shielding gases when heated. This helps protect the molten weld pool from atmospheric contamination, which is crucial for maintaining the quality and integrity of the weld joint.

Shielding Gas: In addition to the flux core, external shielding gas may also be used during ship aluminum alloy welding to create an inert environment around the weld pool, preventing oxidation and ensuring a clean, sound weld. Argon or argon-helium mixtures are commonly used as shielding gases for aluminum welding.

Wire Diameter: Ship aluminum alloy welding wires come in various diameters to match the specific welding requirements and equipment being used. The wire diameter affects the current-carrying capacity and the heat input into the weld.

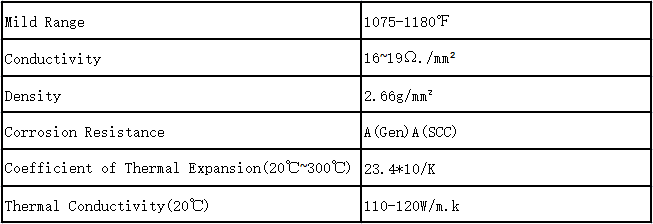

Typical Characteristics

BACK TO TOP