| Quantity: 3 Tons |

| Diameter: 1.2mm |

| Length: 1000mm |

| Material: Aluminum |

9kg Aluminum Welding Wire

Aluminum welding wire is commonly used for marine applications due to its lightweight, corrosion-resistant, and strong properties. It is often used in shipbuilding, boat repair, and other marine-related industries. Welding aluminum in marine environments requires careful consideration of the specific alloy, welding technique, and equipment to ensure the best results and long-lasting welds.

Here are some important factors to consider when selecting aluminum welding wire for marine applications:

Aluminum Alloy: There are various aluminum alloys available, each with different properties suitable for specific applications. In marine environments, alloys like 5052, 5083, and 6061 are commonly used due to their corrosion resistance and strength. 5052 and 5083 are often used in shipbuilding due to their high corrosion resistance and good weldability. 6061 is known for its strength and versatility, making it suitable for various marine components.

Welding Technique: TIG (Tungsten Inert Gas) welding and MIG (Metal Inert Gas) welding are two common methods used for aluminum welding in marine applications. TIG welding provides precise control over the welding process and is often preferred for thinner aluminum sections and critical welds. MIG welding is faster and more suitable for thicker sections. The choice of technique depends on the specific requirements of the marine project.

Wire Diameter: The wire diameter you choose will depend on the thickness of the aluminum being welded. Thinner wire is used for thinner materials, while thicker wire is used for thicker materials. It's important to match the wire diameter with the welding machine and process being used.

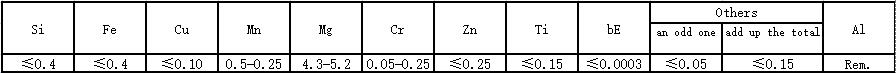

Chemical Composition (weight percent, %)

BACK TO TOP