| Quantity: 3 Tons |

| Diameter: 1.2mm |

| Length: 1000mm |

| Material: Aluminum |

ER5183 Aluminum Welding Wire

ER5183 is a type of aluminum welding wire that is commonly used in the gas metal arc welding (GMAW) process, also known as MIG (Metal Inert Gas) welding. It is specifically designed for welding aluminum alloys, particularly those with similar composition to alloy 5056 or 5083. ER5183 welding wire is known for its good strength and corrosion resistance, making it suitable for applications where the welded joint will be subjected to high levels of stress or exposure to harsh environments.

Key characteristics of ER5183 aluminum welding wire include:

Composition: ER5183 wire is primarily composed of aluminum with small amounts of other alloying elements such as magnesium and manganese. These alloying elements contribute to the wire's strength and corrosion resistance properties.

Welding Applications: This type of welding wire is commonly used in the fabrication and repair of marine, transportation, and structural components made from aluminum alloys. It is also suitable for welding aluminum-magnesium alloy plates and castings.

Welding Process: ER5183 wire is typically used with the GMAW process, which involves feeding the wire through a welding gun along with a shielding gas (usually argon or a mixture of argon and helium). The shielding gas protects the weld pool from atmospheric contamination and helps ensure a clean and strong weld.

Advantages: ER5183 welding wire offers good weldability, high-strength welds, and excellent resistance to corrosion, making it well-suited for applications in environments with exposure to seawater or other corrosive agents.

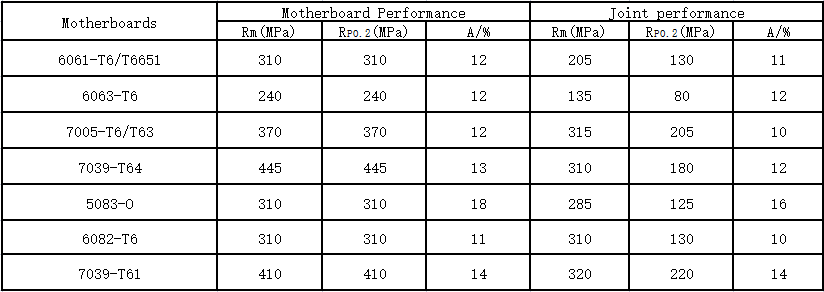

Mechanical Properties of Typical Welding joints (For reference)

BACK TO TOP