| Quantity: 3 Tons |

| Diameter: 1.2mm |

| Length: 1000mm |

| Material: Aluminum Alloy |

GB T 10858 Aluminum Alloy Welding Wire

Aluminum alloy welding wire is used for welding various types of aluminum alloys, including those used in marine applications. Aluminum alloys are commonly used in marine environments due to their excellent corrosion resistance and lightweight properties. Welding aluminum alloys can be a bit challenging compared to welding other materials like steel, as aluminum has a lower melting point and higher thermal conductivity. However, with the right techniques and equipment, successful aluminum welding can be achieved.

When selecting an aluminum alloy welding wire for marine applications, consider the following factors:

Alloy Type: There are various aluminum alloys, each with specific properties suitable for different applications. For marine environments, alloys like 5052, 5083, and 6061 are commonly used due to their corrosion resistance and strength.

Wire Diameter: The diameter of the welding wire should be chosen based on the thickness of the materials being welded. Thicker materials require larger diameter wires to ensure proper fusion.

Wire Type: Aluminum welding wires are available in various types, including pure aluminum (ER1100), aluminum-silicon (ER4043), and aluminum-magnesium (ER5356). The choice of wire depends on the specific alloy being welded and the desired properties of the joint.

Shielding Gas: For aluminum welding, a shielding gas is used to protect the molten weld pool from atmospheric contamination. Argon or argon-helium mixtures are commonly used gases.

Welding Process: Common welding processes for aluminum include Tungsten Inert Gas (TIG) welding and Metal Inert Gas (MIG) welding. TIG welding provides precise control and is suitable for thinner materials, while MIG welding is more versatile and faster for thicker materials.

Preparation and Cleanliness: Aluminum is sensitive to contamination, so proper cleaning of the base metal is crucial. Use stainless steel brushes and acetone to clean the surface before welding.

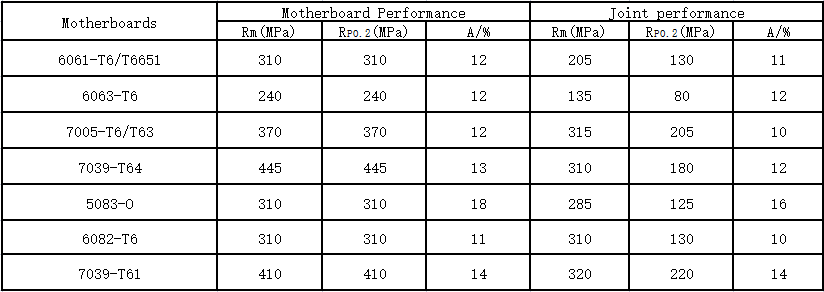

Mechanical Properties of Typical Welding joints (For reference)

BACK TO TOP