| Quantity: 1 Tons |

| Diameter: 1.2mm |

| Length: 1000mm |

| Material: Aluminum Alloy |

DIN EN ISO 18273 Aluminum Alloy Welding Wire

Aluminum alloy welding wire is used for joining and repairing aluminum alloys through various welding processes. Aluminum alloys are commonly used in industries such as automotive, aerospace, construction, and marine due to their lightweight, corrosion-resistant, and high-strength properties. Welding these alloys requires specific considerations and compatible welding wire to ensure proper joint integrity and strength.

Here are a few key factors to consider when selecting aluminum alloy welding wire:

Alloy Composition: Different aluminum alloys have varying compositions, and each alloy type may require a specific welding wire to achieve the desired weld quality. The alloy designation provides information about the alloy's primary elements, such as copper (Cu), magnesium (Mg), silicon (Si), and zinc (Zn). The welding wire should be compatible with the alloy you are working with.

Welding Process: There are several welding processes used for aluminum, including TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), and even specialized methods like friction stir welding. Each process may require a specific type of welding wire designed for optimal performance and ease of use in that particular process.

Wire Diameter: The diameter of the welding wire affects the heat input and deposition rate during welding. Thicker wires can carry more current, which might be beneficial for welding thicker aluminum sections, while thinner wires are better suited for thinner materials.

Welding Gas: In MIG welding, shielding gases like argon or helium are used to protect the molten weld pool from atmospheric contamination. The choice of gas depends on the welding process and the aluminum alloy being welded.

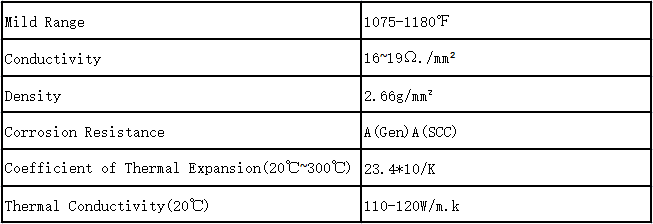

Typical Characteristics

BACK TO TOP